About Us

JIN LI CHENG Milling Cutter Supplier was Founded in 1996.

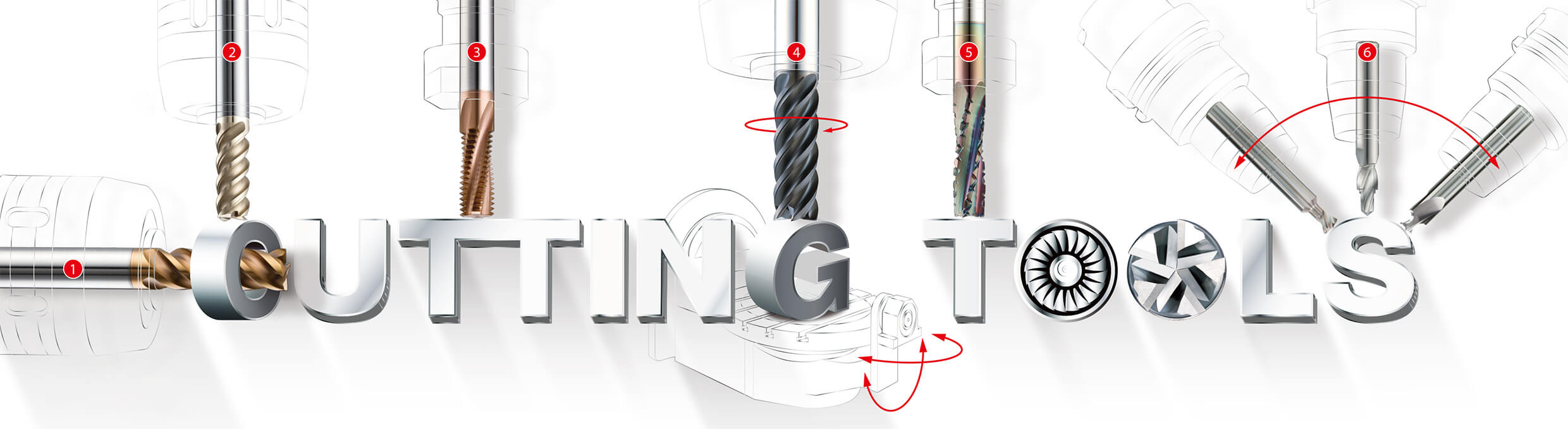

JLC focus on manufacturing, production, research and development, End Mills, Drills, Reamers, and various different solid end mills and tungsten carbide end mill. Your customized demand is our standard, mainly used in aviation aerospace industry, medical industry, car, motorcycle, bicycle, mold, mechanical parts, metal special shape processing.

Mission

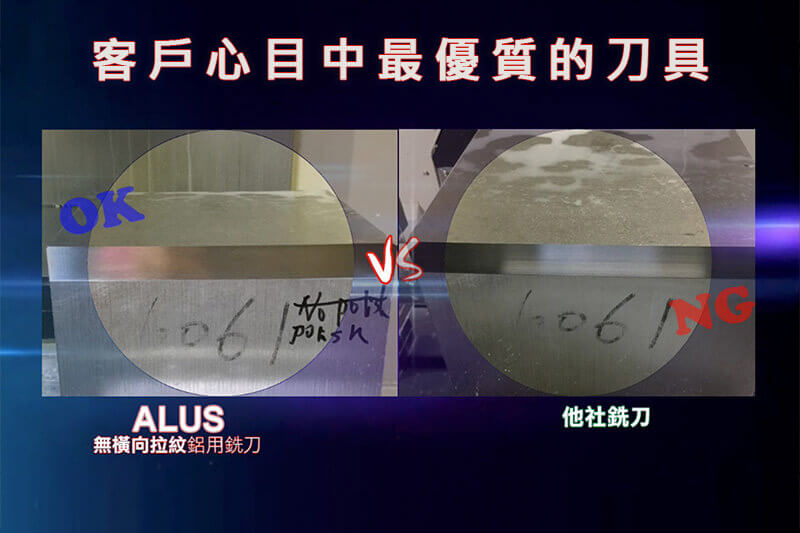

About Jin Li Cheng CNC Milling Cutter Supplier's mission is to provide unique and innovative cutting tools to meet our customers' challenging processing requirements. We are committed to providing quality service, quality products, and building long-term customer relationships. We are proud of the attention to detail and customer care and seek to have fun in our work. Looking for the best CNC Cutting Tool, please contact us!

Customer Service

At JIN LI CHENG milling cutter supplier, our team believes that nothing is more important than us - our customers. Our customer service team is trained to provide timely, friendly, and professional service. When an order needs to be filled out, each cutting tool is manually packaged and the order is rechecked for accuracy before going out. We view your business needs as our own.

Why JIN LI CHENG Milling Cutters Supplier is Different Than Others?

At JIN LI CHENG CUTTING TOOL, we specialize in identifying and providing unique end mills and cutting tool products to meet specific processing needs. Every mill cutting tools in our catalog is in stock. Our unique milling cutters enable our customers to “ready-made” special tools on the same day, eliminating long and expensive lead times.

Custom Cutting Tool Manufacturer

In addition to our unique standard tool products, JIN LI CHENG CUTTING TOOL also offers custom cutting tools. Our custom milling cutter orders range from our standard tools to highly specialized, application-specific custom tools. Call us for help with designing a custom tool, and when you are ready to buy, we will contact you with your local distributor.

Expert Group

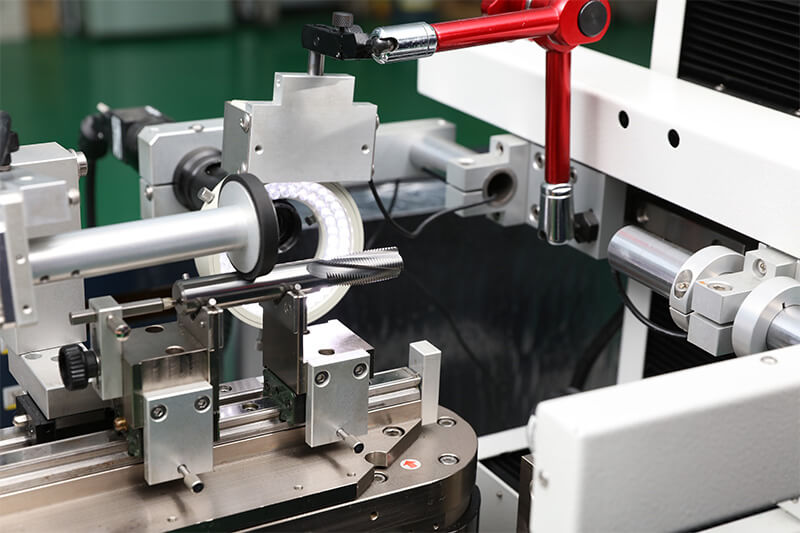

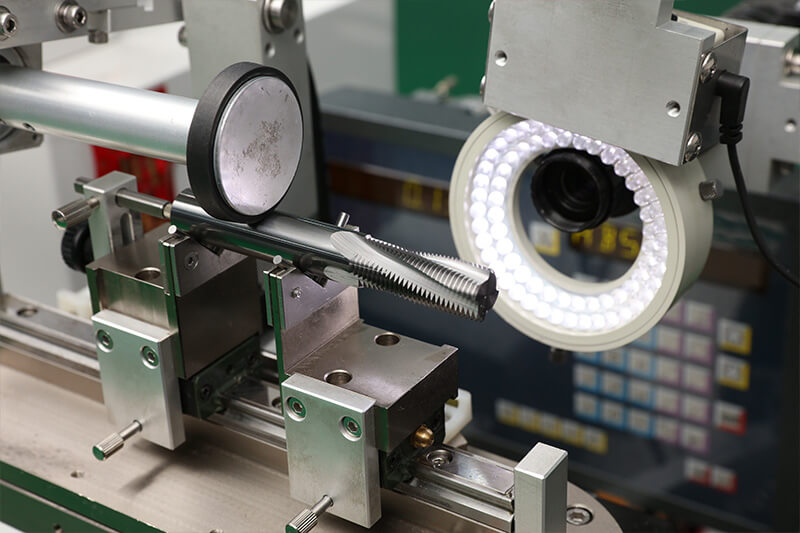

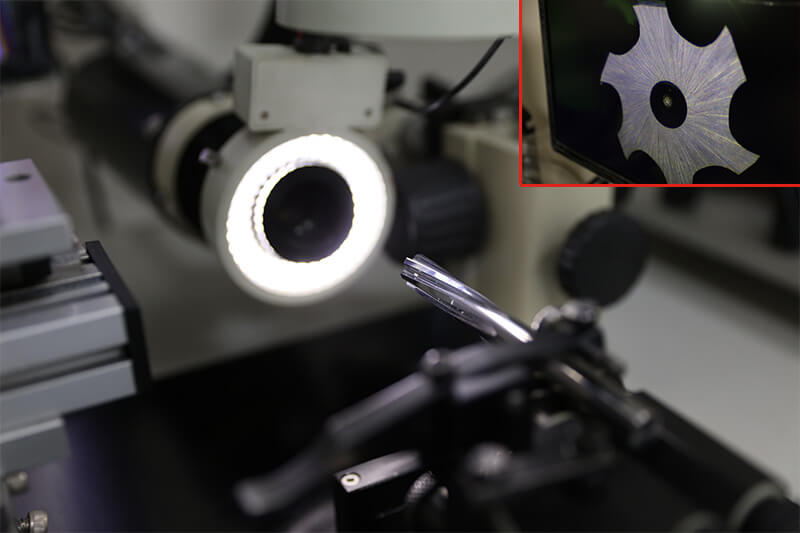

JIN LI CHENG milling cutter manufacturer has a team of highly qualified technical experts and engineers who work together to ensure that we carefully examine every detail from product development to inspection to ensure that each tool meets our standards.

These technical experts can help you with the most challenging applications.

For technical support, please contact us.

Our Commitment to You

JIN LI CHENG CUTTING TOOL's commitment to customers is to provide the best service with the highest quality tools and same day delivery.

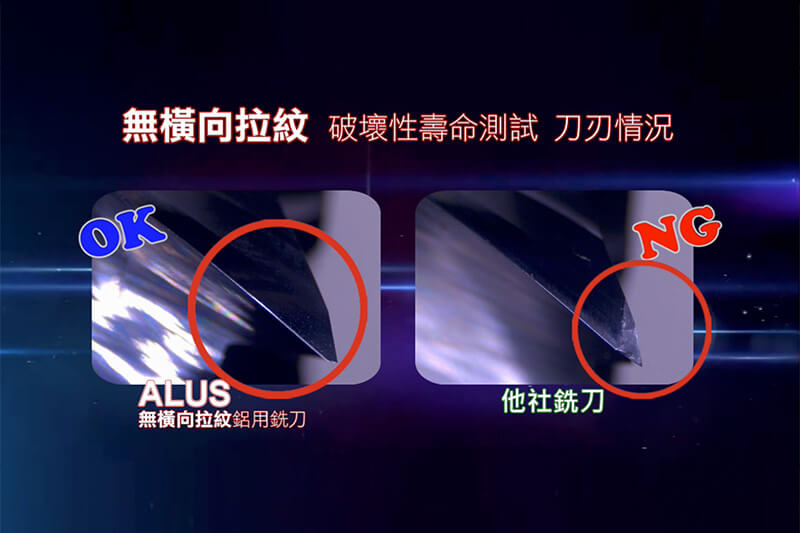

Product Quality

JIN LI CHENG milling cutter supplier develops product specifications by carefully studying and selecting tool geometries to optimize the cutting performance of a given material and application.

We recognize that quality product quality and consistency begins with finding the right quality carbide for the target product and application.

Such blanks are generally closer to the source of tungsten and carbide ore, usually outside Taiwan. Almost all of our tools are CNC grinding in Taiwan using high-precision grinding machines and proven manufacturing methods.

All of these measures help ensure consistency between batches and adhere to strict tolerance standards. For demanding product applications, advanced coatings are applied to maximize performance and tool life. The result is one of the smallest, deepest, and most reliable small diameter and special cutting tool options on the market.