One-stop Services

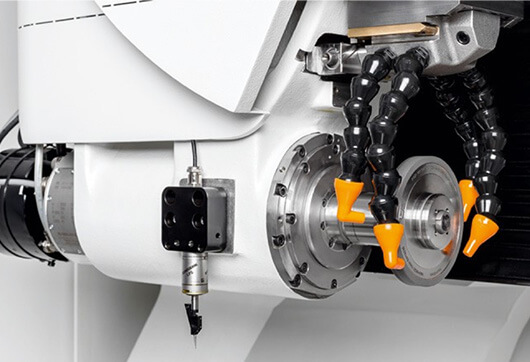

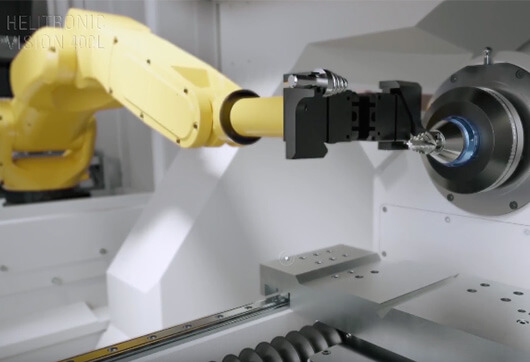

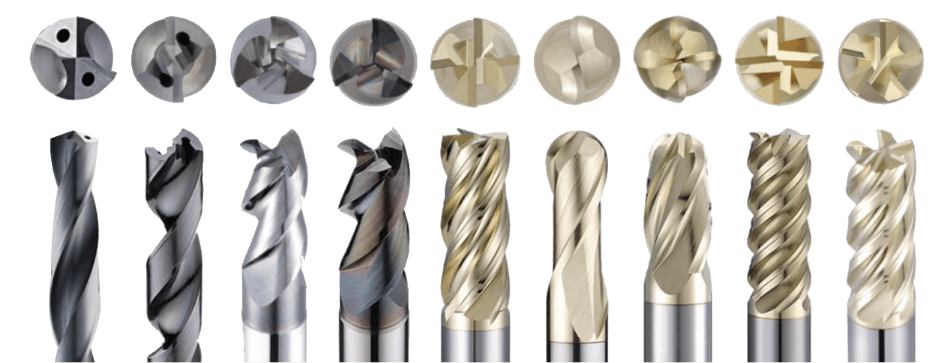

Tungsten carbide cutting tools have become the preferred choice in modern machining due to their excellent hardness, wear resistance, and adaptability. Today, JLC offers one-stop customized services, from consultation, design, and manufacturing to after-sales service.

Consultation

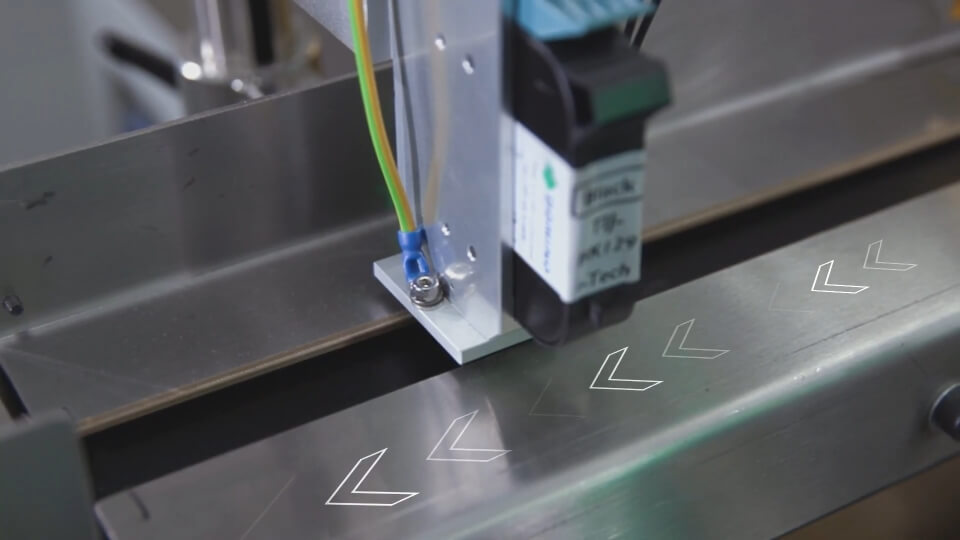

The perfect machining process begins with a comprehensive consultation. Our skilled professional team will work closely with you to understand your specific requirements. Whether you are in metalworking, woodworking, plastic processing, or a DIY enthusiast, we ensure a thorough understanding of your needs before commencing the design process. This step is crucial in providing tools tailored precisely to your unique specifications.